|

A Guide to Implementing the Theory of Constraints

(TOC) |

|||||

|

|

|

|

|

|

|

|

Let’s

Start By Stopping For A Moment Slow down, block out

the rest of the world for a moment, and take the time to consider the

following. Have you ever found

yourself in a situation where you were waiting for someone to provide you

with something, something that you must work on, and in-turn, which you had to pass on to someone else? Someone else who may have also been waiting

for that particular piece of work? And

it wasn’t as though you had no other work – correct? In fact, it is most likely that you were up

to your eyeballs in work, other work – but not the work that you needed at

that moment. In fact its quite likely that you were continuing to receive work

that you didn’t particularly need or want at the moment, and you were passing

on work that others didn’t seem particularly enthused to receive, even if

they had been complaining about it only a few days previous. You probably wondered why you hurried. I doubt that there

are very many who can’t relate to this.

In fact, for many of us, in our day-to-day working lives, it is the

rule rather than the exception. It doesn’t really

matter if you are on the shop floor or in corporate, manufacturing or

services, it pretty much seems universal. Universal or not,

does it need to be like this? I hope to show you

that, indeed, it does not need to be like this at all. What this short

moment of reflection shows is that most of us already have a pretty good

intuition for the concepts of dependency, variation, and an understanding of

systems and therefore the necessary intuition to find the needed

solutions. And really that is all you

require to understand the Theory of Constraints. Theory of Constraints

is the invention of Dr Eliyahu Goldratt, an Israeli physicist, educator, and

management specialist. It’s a business

philosophy

which seeks to strive towards the global objective, or goal, of a system

through an understanding of the underlying cause and effect dependency and

variation of the system in question. It is equally

applicable to for-profit and not-for-profit organizations for; strategy, personnel,

marketing, sales, distribution, manufacturing, design, and project

management. This web site is

designed to be an introduction to some of the important concepts of the

Theory of Constraints and its successful implementation. It is biased a little toward the manufacturing

end of the spectrum. But if you run a

hospital for instance and can’t see the parallels, then please let me know. It is likely that

you will have arrived at this material from a number of different directions; (1) Companies

that are already very successful (we aren’t making enough money). (2) Companies

that are not successful and in need of turnaround (we aren’t making any

money). (3) Not-for-profit

ventures (we can’t achieve sufficient output with our current funding). In each case we are making

insufficient of whatever it is that the organization needs to make in order

to be successful. In other words, we

are, in some way, constrained. Although Theory of

Constraints developed out of for-profit based manufacturing, it has a much broader and more general

applicability. People in

not-for-profit organizations, or service organizations, or a paper-based

transaction will find the principles equally relevant and applicable. Indeed you probably suffer from “flavor

of the month syndrome” – and we all do to some extent – then get your very

best “healthy skepticism hat” out and read on. But consider, also, that the very existence

of something called flavor of the month syndrome must demonstrate a deeper

and on-going need or a desire to improve something – our organizations – our

working lives. The problem seems to be

that we are constantly seeking something out, and constantly being forced to

abandon those methods that fail to deliver the results that we seek. Equally, be aware

that it is almost 30 years since the beginnings of the solution to the problem

that has given rise to the concept of Theory of Constraints, and yet it is

still with us (1). And think of

just-in-time with its beginnings by Eiji Toyoda and Taiichi Ohno in the early 1950’s, and yet

it is still with us (2). What then of

statistical process control with an even deeper past extending back to Walter

Shewhart’s work in the 1920’s, and yet it too is still with us (3). Why is it that

after 30, or 50, or 80 years, these 3 particular methodologies are still with

us, offering solutions that are just as valid today as they were at the time

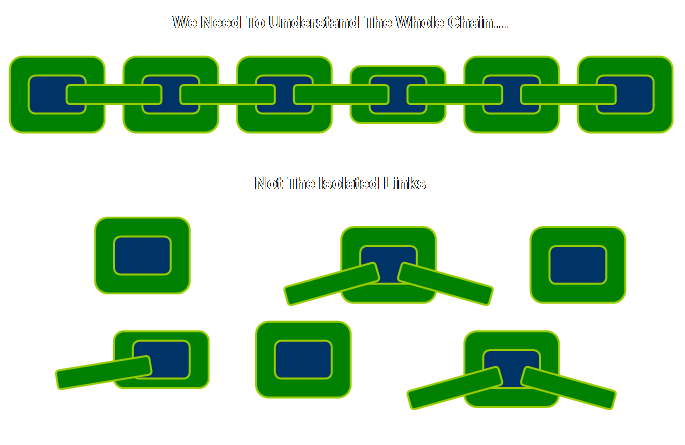

of their inception? Think about it. Why is this? Well all of these approaches are systemic. Note the spelling; it’s not a mistake,

systemic rather than systematic. Certainly

these approaches are also systematic as well as we will shall see, however,

systemic approaches are concerned with the system as a whole, not with parts

of a system in isolation. Think back for a

moment to the introduction when we imagined that we were stuck somewhere in a

process. Did the process look

something like this?

“From a very early

age, we are taught to break apart problems, to fragment the world. This apparently makes the complex tasks and

subjects more manageable, but we pay a hidden, enormous price. We can no longer see the consequences of

our actions; we lose our intrinsic sense of connection to the larger whole.” So we do seem to

have an innate systemic understanding but we tend to still break things down

into sub-parts. Just-in-time,

statistical process control, and Theory of Constraints are all system

approaches. Goldratt characterizes a

system approach as a warning against “concentrating on a local optima (in

place or time) and, by that, jeopardizing the performance of the system as a

whole (5).” More specifically,

statistical process control tells us that “as long as the deviation of a

process is within the statistical boundaries, the biggest mistake a person

can make is to re-align the process.

It is a warning against local optima in time; at this instant you may

think that you have brought the process to be closer to the average but

actually you enlarged the deviation of the system.” With regard to kanban in just-in-time “what

is it if not a technique that is built to prevent the local optima of a

worker producing all the time, producing even when down-stream operations do

not now need the results of his/her work?” In Theory of

Constraints the key to not concentrating on local optima everywhere is

described by a special term – subordination.

We will return to subordination issues often. We mentioned that

all of these methods were systematic as well as systemic. In order to be systematic we need a

focusing mechanism to guide us where to place our attention first, second,

and so forth. The focusing mechanism

for just-in-time

and statistical process control is Pareto analysis; the focusing system for

Theory of Constraints is the 5 focusing steps which we will describe in full

in the page on process of change. Each of these

methods while acknowledging

the overall system also acknowledges that within the system there is

dependency and variation. It is

acknowledgement of variation that sets these particular approaches far apart

from many other business approaches.

Have you ever seen a budget prepared with a target goal +/- some

variation for error? I don’t think

so. The variation is there without

doubt, but it is not acknowledged. And

if it is not acknowledged it can’t be managed. In fact, we manage to try and ignore it by

consistently estimating on the low side with lots of safety tucked away

everywhere. If we have lots of safety

tucked away everywhere then once and a while we should exceed our target goal

– ever wondered why that doesn’t seem to happen? It seems then that we never get to really

know our true potential. Almost by default,

because we have defined a system with boundaries of some sort, we have also

defined that there must be finite capacity within that system. Usually defined by the slowest step in the

process in just-in-time and Theory of Constraints. It is sometimes useful to consider this

step as the weakest link in a chain.

And just as you can ignore the weakest link in a chain, but the weakest

link won’t ignore you, so too can you ignore the slowest step in a process but

the slowest step won’t ignore you. In

other words, regardless of what you do, the slowest step or weakest link will

determine the rate or strength of the whole system. Batching is

something manufacturing people do – right?

Well then consider this. Have

you ever heard someone say to you; “Well, we like your idea but we can’t

consider your proposal/request until next week when we usually consider

these?” Ah, that sounds like batching

to me, batching in time. How about; “Yes,

we like your idea but we can’t process your application until we have a

sufficient number, please put it over there.”

Ah, that sounds like batching too, batching in quantity. You see we are all surrounded by batching

actions, some so common we hardly think about it at all. Is this important? Well I think so, especially if you consider

the comments about dependency and variation.

Batching increases the variation in the system and exacerbates the

dependencies. Imagine you are a

downstream step from a batching operation of some sort. Maybe towards the end of the current batch

you are beginning to run out of work, you slow down, it’s important to keep

busy after all. But it’s also like the

calm before the storm; you know that when the next lot of work is released

then suddenly you will have a lot of work on your hands and you will have to

work quite quickly to move some of it through. So the work load is variable for no other

reason than we had to batch before your position in the process. Variation increases with batching. The batching also

highlights dependency. You probably

had productive time towards the end of the last batch – that calm before the

storm – but you couldn’t use it. It

was lost to the system, and now that you are in the middle of the current

batch – up to your neck in work – you have no excess or spare capacity to

call upon to help you. If only you

could have somehow magically stored that capacity from the quiet period and

shipped it to the busy period when it would have been useful. So, batching also highlights dependency. There are strong

parallels between the systemic approaches we have been talking about and the

concepts of detail and dynamic complexity of Senge.

In the Fifth Discipline he describes these

two types of complexity (4); (1) Detail

complexity – the sort where there are very many different variables to

consider. (2) Dynamic

complexity – the sort where cause and effect are subtle and the effect over time is not obvious. In operating a

process, regardless of whether it is a small job shop or a huge factory, and

regardless of whether it contains highly variable human patients or uniform

mechanical parts, is full of detail complexity. However the underlying dynamics are limited in

variety and not particularly complex. When someone tells

you that there are 17 different ways to grind a drill shank they are telling

you about detail complexity. When

someone tells you there are 3000 stock items, again they are telling you about detail

complexity. However, when an

action has different effects over the short run and the long run we are

really looking at dynamic complexity.

When an action has one set of consequences locally and a very

different set of consequences in another part of the system, then there is dynamic complexity. When obvious interventions produce

non-obvious consequences, there is dynamic complexity. “The real leverage

in most management situations lies in understanding dynamic complexity, not

detail

complexity (4).” Restated; the real

leverage in most management situations lies in understanding cause and effect

dependency and variation. Let’s be clear

then, there is nothing wrong with detail complexity when it is applied to

various attributes of products in a process. In fact,

you already have the expertise to deal with this; otherwise you wouldn’t be

in business. The error, if you like,

is when we attempt to apply detail complexity to the process that produces

the products. This is the domain of

dynamic complexity. We can combine the

dynamic and detail complexity concepts of Senge with the global objective

versus local objective concepts of Goldratt in a simple 2 by 2 matrix. This is what we get.

This gives us two

diametrically opposed concepts. The

first is a combination of dynamic complexity and global optimization which we

will call the systemic/global optimum approach. The second is the combination of detail complexity

and local optimization which we will call the reductionist/local optima

approach. These are two key concepts

that underline much of the discussion and development in the following pages. Let’s list these for further clarity; (1) Reductionist/local

optima approach. (2) Systemic/global

optimum approach. They represent two

different lenses through which we can view our organizations. Let’s return to

Senge once more; “The most powerful learning comes from direct

experience. Indeed we learn eating,

crawling, walking, and communicating through direct trial and error – through

taking an action and seeing the consequences of that action; then taking a

new and

different action. But what happens

when we can no longer observe the consequences of our actions? What happens if the primary consequences of

our actions are in the distant future or in a distant part of the larger

system within which we operate? We

each have a ‘learning horizon,’ a breadth of vision in time and space within

which we assess our effectiveness.

When our actions have consequences beyond our learning horizon, it

becomes impossible to learn from direct experience (4).” “Herein lies the core learning dilemma that

confronts organizations: we learn best from experience but we never directly

experience the consequences of many of our most important decisions.” What if there was

a simple way to verbalize and capture the cause and effect which we never directly experience, but

which we none-the-less have the intuition for? What if we could overcome this core

learning dilemma? Senge proposed

computer-based “microworlds,” but what if we could do it on the back of an

envelope – pen and paper? There is a

mechanism that allows us to verbalize, construct, analyze, and communicate

these cause and effect relationships, and moreover, to propose workable

solutions to the problems that they cause.

This is known as the Thinking Process. Mention of the Thinking Process brings

us to the concept of elegance. In the

sciences the meaning of elegance is one of simplicity and ingeniousness. An elegant solution to a problem is a cause

for considerable respect. Theory of

Constraints seeks elegant solutions to problems, rather than sophisticated

ones. Elegant solutions are more

likely to have broken some deeper core or underlying problem; sophisticated

solutions are likely to have addressed a limited number of higher order

problems (symptoms) while leaving the underlying core problem unresolved. The solutions may

be elegant, but they are also incredibly robust. This robustness means that doing something,

anything, which is aligned with the direction of the solution, is most likely

to bring about an improvement or movement towards that improvement. In contrast the surest way to fail is to

sit around measuring and data gathering and waiting until you are sure your

implementation will be perfect. It

won’t be perfect because it will never start.

Robust solutions can stand a lot of rough handling. The best thing to do then is to do

something. If a picture is

worth a 1000 words, then please accept the following as a visual summary.

Most of all,

Theory of

Constraints is a work-in-progress. It

continues to

evolve into new areas as people discover its broader applicability and it

also continues to improve in delivery in established areas as people refine

their approaches. Hopefully you have

been armed with some key concepts. We

want to improve systems. We need to recognize that

dependency, variation, and finite capacity exist in these systems. We need to understand that seemingly

complex cause and effect occurs via these dependencies, both in time and in

space, and this has been termed dynamic complexity. Understanding these features is the key to

gaining control and moving our system in the direction that we desire. Let’s have look

then at the effect of this on the bottom line. (1) McMullen, T.

B., (1998) Introduction to the Theory of Constraints (TOC) management

system. St. Lucie Press, pg 114. (2) Ohno, T.,

(1978) Toyota production system: beyond large-scale production. English translation, Productivity Press, pp

75-92. (3) Lepore, D.,

and Cohen, O.,

(1999) Deming and Goldratt: the Theory of Constraints and The System of

Profound Knowledge. North River Press,

pg 45. (4) Senge, P. M.,

(1990) The fifth discipline: the art & practice of the learning

organization. Random House, pp 3, 23,

71-72. (5) Goldratt, E.

M., In: Cox, J. F., and Spencer, M. S., (1998) The constraints management

handbook. St Lucie Press, pp ix-xi. This Webpage

Copyright © 2003-2009 by Dr K. J. Youngman |