|

A Guide to Implementing the Theory of

Constraints (TOC) |

|||||

|

Competitive

Advantage – Short Lead Times “If the market

is dominated by a poorly performing organization and I want to take the

market, all I have to do is develop a more responsive order fulfillment

process. I do not need a higher

quality product, a more advanced product, or even a cheaper product. If I care for your customers better than

you do, they will be mine (1).” Lead time can be an extremely important competitive

advantage when stock is not held in advance.

Many organizations, including many not-for-profit and service

organizations where the customer is directly involved in the process, are

essentially make-to-order businesses.

You can’t store the finished product ahead of time; thus lead time is

of critical importance. Many

manufacturing and process organizations are also make-to-order. The order might be for a standard item or

it might be for a unique “special” item that has to be designed first,

however, it can still be made and delivered to the customer within the

time-frame that the customer is willing to wait. Make-to-order businesses, whether service

or production based, for profit or not-for-profit, can directly benefit from

lead time reduction due to the removal of excess work-in-process, smaller

transfer batches, and/or smaller process batches. Lead time is a

very important component in a customer’s perception of business

performance. In a make-to-order

business the lead time has a direct impact on the business and on the

customer. Total lead

time is the result of total work in process (manufacturing lead time). This is primarily driven by; (1) Excessive queue time/work-in-process. (2) Batching of

product. (3) Batching in

time. Let’s look at

each of these in a little more detail. We have seen

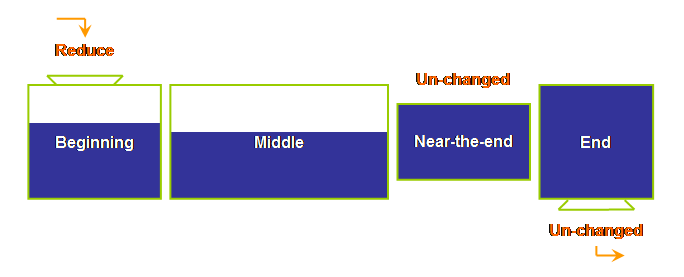

that in a production constrained system it is possible to introduce

drum-buffer-rope and thereby increase the output, which has the effect of

reducing the lead time by reducing the overall level of work-in-process. Let’s call this “drying the system

out.” In the situation here where we

have a market constrained system, we can not increase the output – it has no

where to go – so we must reduce the input for a while in order to dry

the system out.

If we decrease

the physical batch size we will reduce the amount of time spent in the

process and this too will decrease the lead time. We dealt with this in some depth in the

production section on batching. It may

be worthwhile to check this again.

Essentially there are two ways to approach lead time reduction in a

make-to-order environment, either splitting batches into sub-batches while in

the process – transfer batching – or releasing smaller discrete batches more

often – process batches. Of the two,

transfer batching offers the potential for the greatest decrease in lead

time. Reductions in lead time of one

half to one quarter or less are quite possible. Single-piece-flow is the ultimate version

of transfer batching. If we increase

the frequency of our schedule we will reduced the amount of time an order

waits before it is launched to manufacturing.

Don’t worry, there are organizations that still batch their schedule

once a month or once a fortnight – we should be looking at once a day. This reduces but doesn’t completely remove

batching in time effects. Reducing the

input using drum-buffer-rope will decrease the lead time. Increasing the scheduling frequency will

decrease the lead time, and decreasing either transfer batch or process batch

size will decrease the lead time.

Having faster service levels than you competitors will stimulate

demand for your products. In fact

because you are have spare operational capacity you can segment your market a

little and make even more money. Let’s

have a look at that. If our actual

manufacturing lead time is shorter than our quoted standard lead time, or if

we have a lot of spare capacity, or we can reduce transfer batch size on

“hot” orders easily, then offering a premium “rush” service at a premium

price is a tactic to increase cash flow.

Aim to bring in new customers who haven’t yet availed themselves to

the standard service – they soon will. Conversely,

customers with time to spare are also a good source of additional revenue

(2). Again it is dependent upon having

sufficient spare capacity on hand. By

offering a discount for long lead time for additional work, we can slot this

work in to fill-out your work load.

Care needs to be taken to segment these clients (isolate them) from

the standard work, or else we will simply downgrade (discount) our existing

clients without increasing throughput.

Again we are aiming to bring in new customers or new work that hasn’t

yet availed itself to the standard service. Having a

shorter lead time than competitors in a market constrained make-to-order

environment is a significant commercial advantage. Obtained a shorter lead time is mostly

policy driven in the form of reduced total work-in-process, reduced transfer

or process batch size, and increased frequency of scheduling. (1) Woeppel,

M. J. (2001) Manufacturer's guide to implementing the theory of constraints,

pg 22. (2) Newbold,

R. C (1998) Project management in the fast lane: applying the theory of

constraints, pp 126-129. This Webpage Copyright © 2003-2009 by Dr K. J.

Youngman |